Test Model for Nano Diamond Filament

The Nano Diamond filament was tested according to GOST 11262-80 requirements for curable injection-molding resins. The samples for testing were shaped as cylindrical bars with thicker ends for mounting in clips (Type 4) (see fig. 1).

Fig.1 Sample for tensile test

Binder Preparation and Curing Process

For binder preparation, we used Epicure UP-632 epoxy resin, Epikote hardener, and UP-606/2 accelerator for epoxy resins. Diamond nanoparticles were dispersed in the colloidal solution of the hardener with different concentrations.

The following colloid-based binder compounds were obtained:

- It contains 0% nanoparticles (pure hardener);

- containing (confidential)% Nanodiamonds (pure hardener and colloid 1:1);

- containing (confidential)% Nanodiamonds (colloid with Nanodiamonds);

The ready binder was poured into a pre-treated metal mold. Pretreatment of the mold included cleaning of the surface from any contamination, degreasing with alcohol, and application of separator. The KPD silicone lubricant was used as a separator.

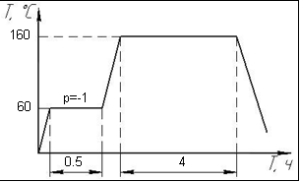

The binder was cured with exposure to vacuum for thirty minutes at 60˚С to eliminate bubbles and exposure to a high temperature of 160˚С for 4 hours to ensure polymerization according to the curve shown in fig.2.

Fig.2. The polymer composite product molding process

After cooling the samples, started the process of removing mold, clearing spews, and examination. Then the obtained samples were marked, and their precise geometrical dimensions were determined.

Fig.3 Samples for tensile testing

Nano Diamond Filament Testing procedure

A tensile-testing machine is used to measure the tensile strength. It’s done by a smooth increase of sample loading with constant speed until it is destroyed. A sample is fastened by the clamps of the tensile testing machine (see fig. 4). Then, start moving the clamp. After that, smoothly increase the tensile load until the sample is destroyed.

Fig.4. Tensile testing procedure

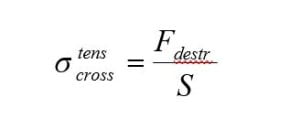

Meanwhile, the force value recorded was enough to destroy the sample. The tensile strength of the material was determined as destroying force value divided by the cross-section area of the tested sample, i.e.:

Nanodiamods equation – The tensile strength of a material

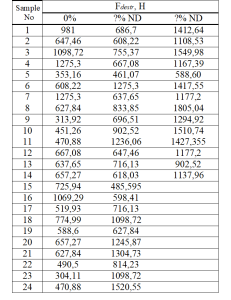

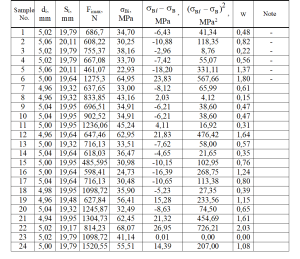

The destroying force values are shown in Table 1 below.

Table 1. Destroying force value during tensile testing of the samples

Analysis of the results obtained

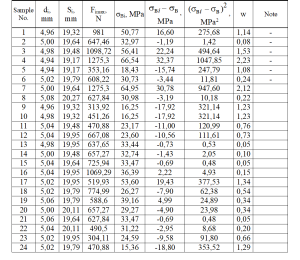

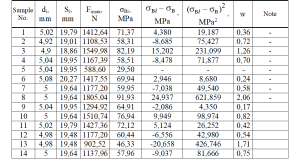

The tensile strength of the tested material determined an average value for random sampling from one sample lot. Statistical treatment of the results, which determined the tensile strength of the materials, are shown in the tables below. According to the Chauvenet criterion, a relative deviation w was calculated for each sample and compared to the standard value w0.

Then, a decision was made, whether to keep or exclude this particular value. If any value was excluded from the sampling range, then average and standard deviation values were calculated for such modified sampling. Processed results of testing are shown in tables 2 to 4.

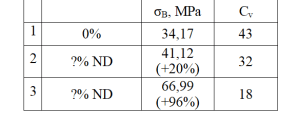

Comparative data on tensile testing of the materials are shown in Table 5.

Table 2. Statistical treatment of tensile testing results to determine the tensile strength of the samples containing 0 % (pure hardener)

Table 3. Statistical treatment of tensile testing results for the purpose of determination of tensile strength of the binder samples containing ?% Nano diamonds

Table 4. Statistical treatment of tensile testing results to determine the tensile strength of the binder samples containing ?% Nano Diamonds

Table 5. Tensile strength values for tested material samples with experimental data variation coefficients

Findings

- The positive effect of nanoparticles on the mechanical properties of epoxy binder shows a significant increase in tensile strength.

- During those studies, new production techniques were tested that allowed the authors to achieve excellent results.

Factors and techniques affecting the strength properties of carbo plastics should be studied in a more controlled and exacting manner.

Conclusion

Nano Diamond filament adds significant strength, and it can be applied to an extensive range of materials. Strength enhancements are likely to displace heavier traditional materials. It allows composites to be used in previously unimagined roles. Composites utilizing Nano Diamonds may also be used in the fabrication of premium products that are valued for their durability and lightweight.

In our opinion, our Nano Diamond composite will enable stable and impressive results in the improvement of strength properties of polymer composite materials.

Authors

Borodin, Vladimir, Ph.D., Physics Factor,

Factor, Andrey, BSME

Weingarden, Marshall, BA

Copyright 2011-2021, Nano Materials and Processes, Inc. All rights reserved.