Our Army Green ASA filament (Acrylic-styrene-acrylonitrile copolymer) is a thermoplastic elastomer. It has high UV irradiation resistance. Also, it is resistant to heat, moisture, and stress cracking. It has one of the best weathering resistance properties in the 3D printing industry.

With high chemical resistance and impact strength, ASA mechanical properties are very similar to acrylonitrile butadiene styrene (ABS) elastomers. With no double bonds in the polymer backbone, our ASA filament has better long-term heat and chemical resistance when compared to diene rubbers.

Army Green ASA Filament ASA Printer Settings

| Nozzle Temperature | 240°C – 260°C |

| Bed Temperature | 80°C -100°C |

| Cooling | Off or Low (5%-20%) |

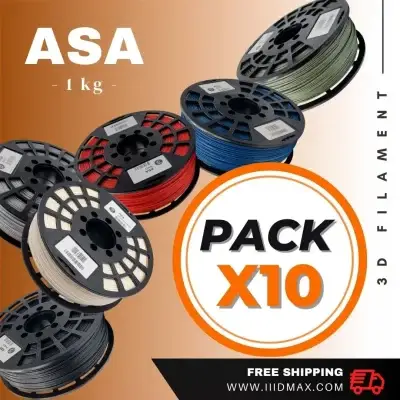

ASA Filament Options

ASA Applications

ASA filament has many applications and uses. It is extensively used in the real estate industry (construction, appliances, etc.). In addition, it is also used for automotive body parts, like mirrors.

![Army Green ASA Filament 1kg [NEW]](https://www.iiidmax.com/wp-content/uploads/2022/06/Asa-Army-Green-1kg.webp)

![Army Green ASA Filament 1kg [NEW] - Image 2](https://www.iiidmax.com/wp-content/uploads/2022/06/ArmyGreen-Asa-info.webp)

![Army Green ASA Filament 1kg [NEW] - Image 3](https://www.iiidmax.com/wp-content/uploads/2022/06/ArmyGreen-Asa-front.webp)

![Army Green ASA Filament 1kg [NEW] - Image 4](https://www.iiidmax.com/wp-content/uploads/2022/06/ArmyGreen-Asa-box.webp)

![Red ASA Filament 1kg [NEW]](https://www.iiidmax.com/wp-content/uploads/2022/06/Asa-Red-1kg-400x400.webp)

![Antique White ASA Filament 1kg [NEW]](https://www.iiidmax.com/wp-content/uploads/2022/06/Asa-Antique-White-1kg-400x400.webp)