3D printing issues might arise throughout your printing experience. We’ve all encountered ourselves trying to fix printing problems and getting nowhere.

Directly from our 3D printer troubleshooting experience, we put together a comprehensive guide on common 3D printing problems & solutions. We will dive into 3D print layer shifting and how to prevent print warping, stringing, over-extrusion, and print bed adhesion. Apart from all the following printing problems and solutions, you have to consider external factors such as humidity.

This is why it is imperative to start your 3D printing process with dry filament.

3D Print Stringing

Stringing is one of the most common 3D printing problems. When the nozzle moves from one point to another, it might lose plastic that solidifies, leaving a visible string of plastic that looks like “plastic hair”.

How to Solve Print Stringing?

The first thing to consider is printing temperature. Different types of filament vary their printing temperatures. When 3D printing process starts, the filament starts melting down through the nozzle. If you set your temperature too high, then you will notice the strings. If you set your temperatures too low, then you might block your nozzle. Printing a temp tower can help you out. Make sure you check the printing temperatures below.

Filament Printing Temperatures

PVA: 160-190°C

PLA: 180-220°C

ABS: 200-250°C

PETG: 220-255°C

TPE: 210-240°C

TPU: 230-250°C

ASA: 230-260°C

Click here to dive deeply into 3D Print Stringing Troubleshooting

3D Print Layer Shifting

Regardless of the printer material (PLA, PETG, ASA, etc.), this problem affects the print’s visual appearance and dimensions. It can happen throughout the printing with slight movements off place or with a singular large displacement at a specific layer.

There is no solution for the 3D print layer shift problem after it happened.

How to Solve Layer Shifting?

To solve 3D print layer shifting, you will need to calibrate your printer correctly. Make sure it’s not loosened, and it might shake while printing. Also, If you are running prints non-stop, electronic pieces can overheat, leading to malfunctioning. In addition, check your printer belts. Make sure they are not too stretched. The pulley might be rotating, but the belt is not moving. Finally, set the correct filament printing temperature. Printing temperatures vary between different 3D filaments.

Click here to dive deeply into 3D print layer shifting troubleshooting

3D Print Warping

If you notice that the corners of your 3D models are bending and starting to deform while you are printing, then you might be suffering from 3D Print Warping.

How to Solve Warping?

First, if you have external cooling, consider disabling it and testing it. Cooling can be a real problem when printing with high-temperature 3D filaments like ASA or PETG.

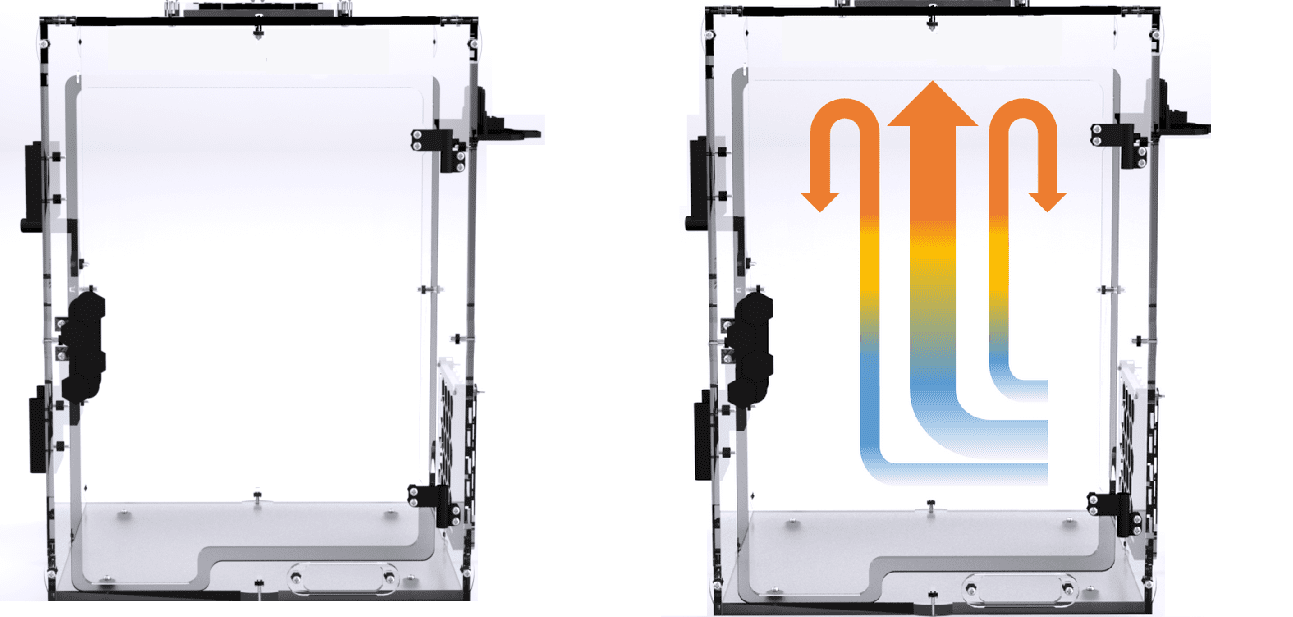

Also, plastic tends to shrink as it cools down. This is why people tend to use heated enclosure methods, which can keep the bottom layers of your part warm.

Click here to dive deeply into 3D Print Warping Troubleshooting

3D Print Not Sticking to Bed?

If you have experienced this problem, don’t worry, we have solutions for you. If your first printed layer is not sticking to the bed, the rest of your project will be compromised.

How to Solve Bed Adhesion Issues?

The first thing you need to do is check if your platform is leveled properly. If you don’t level your bed platform correctly, a whole print might fail to adhere to the surface. Then, your 3D printing will not stick to its bed properly if your extruder releases high temp 3D filament and your bed is cold. This is why it’s imperative to understand your printing temperature & settings. Also, review your printing speed. When your printing speed is too fast, your print might not adhere properly.

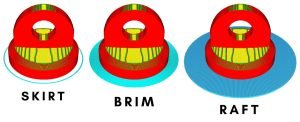

Key tip: you might want to secure your bed adhesion with rafts, brims, or skirts.